-

Fundamentals of Monochromatic Excitation Energy-Dispersive X-ray Fluorescence Spectrometry

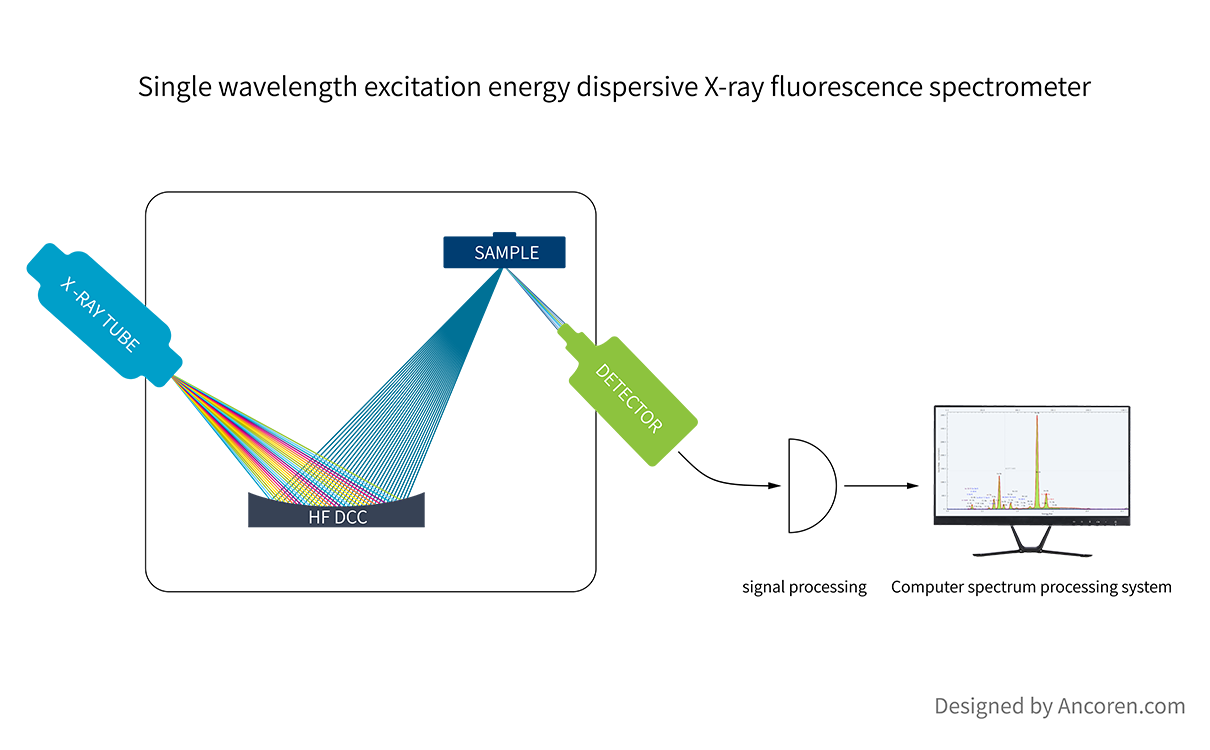

1)Monochromatic Focused Excitation Technology

Micro-focus X-ray tube emission is monochromated and diffracted to the sample point via full-focusing doubly curved crystal (Johansson type DCC), achieving point-to-point high-intensity monochromatic diffraction. This significantly reduces bremsstrahlung-induced scattered background interference and enhances elemental detection sensitivity.

2)High-Performance SDD Detector

Monochromatic excitation technology synergizes with SDD detectors, maximizing count rate and resolution to enable simultaneous detection of major and trace elements.

Monochromatic X-ray Fluorescence Spectrometer MERAK-SC

Energy-dispersive X-ray fluorescence spectrometry (EDXRF) lacks capability for light element analysis and typically cannot quantify ultra-light elements (C, N, O, F, Na, etc.). Beyond low fluorescence yields, a key limitation is continuous background interference from bremsstrahlung scattering, which obscures light element signals. This is where EDXRF underperforms compared to wavelength-dispersive XRF.

MERAK-SC employs monochromatic focused excitation to dramatically improve light element sensitivity. Its ultra-thin graphene-window SDD detector enhances transmission for ultra-light elements (O, F, Na, etc.), matching the performance of large WD XRF systems.

Secondary target technology enables analysis of major elements (K-Cu).

Equipped with Holospec FP 2.0 fundamental parameters method, it rapidly develops analytical methods for diverse samples, enhancing adaptability and quantification accuracy.

- Ultra-low detection limit of light elements

Extends elemental analysis to ultra-light elements, e.g., achieving unprecedented 0.15% detection limit for fluorine (F).

Elemental Analysis Range

Light Elements: O, F, Na, Mg, Al, Si, P, S, Cl

Metal Elements: K, Ca, Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn

Liquid Sample Analysis

Specialized sample cup for liquid analysis.

Top-Down Geometry

Prevents optical path contamination or detector damage from surface dust/liquid spills.

Auto-Rotating Sample Stage

Software-controlled rotation improves precision for heterogeneous samples.

Temperature Control

Ambient temperature range: 24±3°C, control accuracy: ±0.3°C.

Holospec FP 2.0 Software

Powerful fundamental parameters method with visual interface for application development.

- Principle

Monochromatic excitation energy-dispersive X-ray fluorescence spectrometry

Powerful Holospec FP 2.0 software with visual interface supports diverse sample applications.

Elemental Analysis Range

Light Elements: F-Cl

Metal Elements: K-Zn (other elements configurable)

Element Detection Limits

Note: Analysis time 300s. Detection limits vary with sample matrix. Values based on aqueous matrix.Elements F Na\Mg Al\Si P\S\Cl K-Zn Detection Limit(%) 0.15 0.005 0.001 0.0002 0.0003

Repeatability

Content

Analysis Time: 30-300 seconds/sample

Stability: ±0.5% over 24 hours; <±1% within one week.

Note:Relative change in element content or intensity

- 1. Elemental analysis of cement raw materials (limestone, etc.), kiln feed, cement clinker.

2. Simultaneous rapid detection of S/Cl/F in solid waste.

3. Coal elemental composition analysis; calorific value & ash content prediction; fly ash/gangue analysis.

4. Petrochemical elemental content analysis.

5. Soil major components (oxides) & trace elements (P, S, Cl, etc.).

6. Major/minor impurity analysis in ferrous/non-ferrous metallurgy.

7. Aluminum industry elemental analysis.

8. Limestone major element analysis.

9. Magnesite elements/oxides analysis; magnesia impurity detection.

10. Graphite/carbon industry elemental analysis.

11. Lithium battery major elements & trace impurities analysis.

Simultaneous S/Cl/F Analysis in Solid WasteS/Cl/F content is mandatory for waste treatment facilities. Current methods lack simplicity and simultaneity. MERAK-SC enhances light element sensitivity via monochromatic excitation, enabling synchronous F/S/Cl/major element analysis. Holospec FP 2.0 improves precision and adaptability, with simple prep and rapid detection for scientific waste management.

Magnesite Elemental Analysis

Magnesite (MgCO₃) is the primary natural resource for magnesium refractories. Global reserves total ~12 billion tons, ~5 billion in China. Impurities (CaO, SiO₂, Fe₂O₃, Al₂O₃) degrade refractory properties and complicate processing, making impurity analysis critical.

Soil Nutrient Element Analysis

Conventional methods require multiple techniques for dozens of elements, with complex prep and low efficiency. MERAK-SC simultaneously quantifies major/trace elements (Na, Mg, Al, Si, P, S, Cl, K, Ca, Mn, Fe, Zn) in soils, offering simple prep, rapid analysis, high accuracy, and low cost.

- HOME

-

PRODUCT

- SOLUTION

-

- ENVIRONMENTAL PROTECTION

- Real-time monitoring solutions for heavy metal emissions in air and water

- Detection of heavy metal content in soil environment

- Simultaneous determination of solid waste (S, Cl, F)

- Analysis of soil nutrient content

- Detection of toxic elements in solid waste and hazardous waste

- Emergency monitoring of Heavy Metals in Environmental water quality

- PM2.5 air filter membrane inorganic element content analysis

-

- METALLIC ORE

- Cu/Cr/Ni/Mn Ore Element Content Detection

- Elemental content analysis of Copper concentrates

- High purity metal (alloy) content analysis

- Elemental content analysis of slag samples

- Rapid determination of precious metal content in ternary catalyst

- Determination of element content in magnesite and magnesite

- Rapid analysis of rare earth elements content

- Rapid trace precious metal content testing

- XRF LIBRARY

- SERVICE&SUPPORT

- ABOUT ANCOREN