Application overview

Rare earth is known as "industrial gold" and has extremely important application value in military, metallurgy, petrochemical, electronic materials, glass ceramics and other fields. In the process of rare earth exploration, mining, beneficiation, processing and trade, the content determination of rare earth elements runs through them. There are 17 rare earth elements in total, most of which are close to each other in terms of element ordinal number and physical and chemical properties, which bringing challenges to various spectral detection methods. Conventional methods for detecting element content in rare earths include ICP-AES, ICP-MS, etc., which require wet digestion of rare earth minerals or products, with long analysis cycles and high detection costs.

X-ray fluorescence spectrometry (XRF), as one of the elemental content analysis instruments, has been widely concerned and valued by elemental analysts for its non-destructive, simple sample processing and low detection cost. For many years, XRF has been challenging for the analysis of rare earth elements. First, the fluorescence lines (K line series) of most rare earth elements are above 33KeV, and the X-ray tube excitation and detector detection efficiency are low; secondly, the software system using empirical coefficient quantification method requires large number of standard rare earth samples, which is obviously unrealistic.

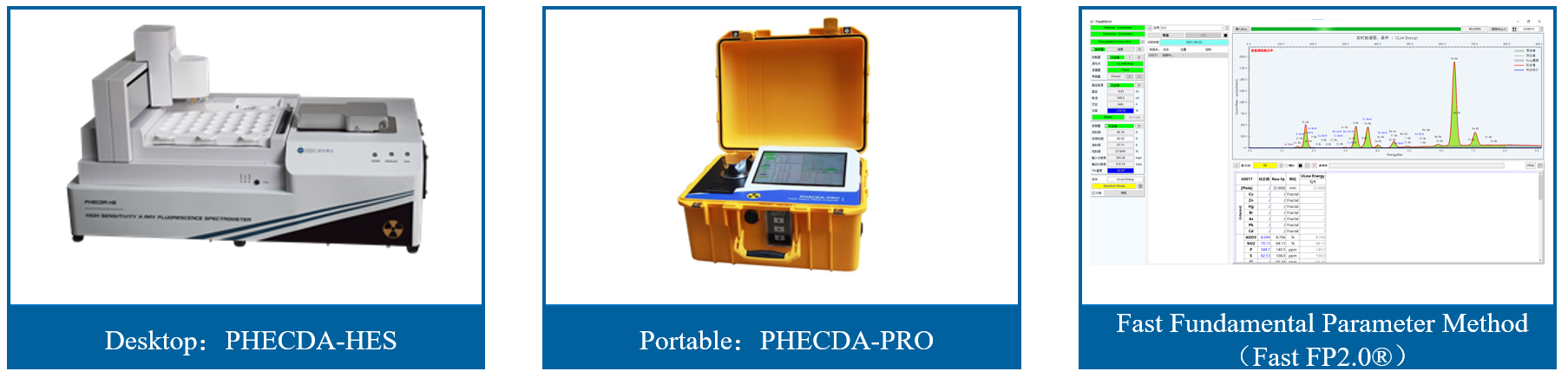

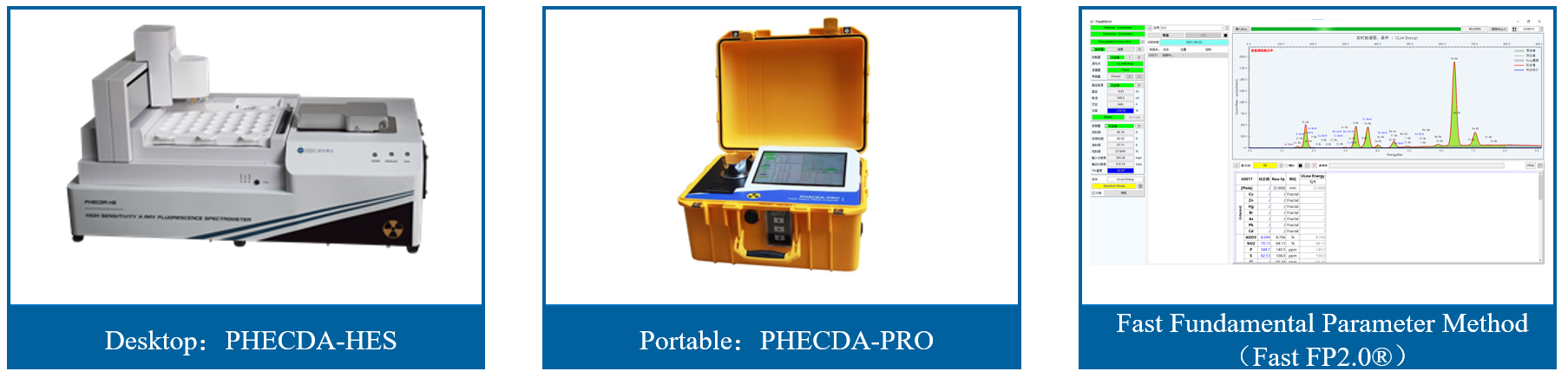

The single-wavelength excitation-energy dispersive X-ray fluorescence spectrometer developed by Ancoren has greatly improved the excitation efficiency of rare earth elements, and the element analysis range covers all rare earth elements. The software is based on the fast fundamental parameter method with independent intellectual property rights, improves the detection accuracy of rare earth elements in the case of using a small number of standard samples.

The combination of single-wavelength excitation-energy dispersive X-ray fluorescence spectroscopy and fast fundamental parameter method brings a new analytical method for the detection of rare earth elements.

Technical Principle

(1)Hardware core technology

single wavelength excitation energy dispersive X-ray fluorescence spectrometer(HS XRF®)

patent of invention【Patent No: ZL 2017 1 0285264.X】

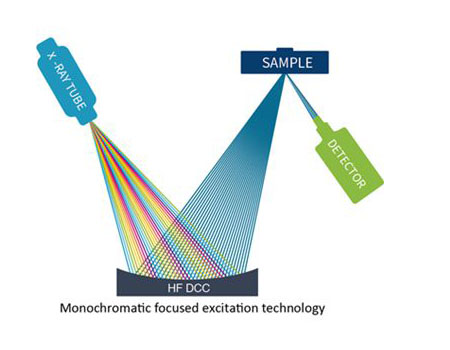

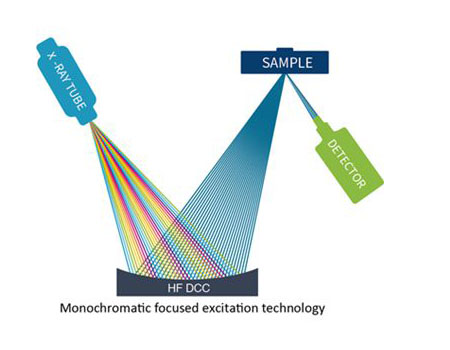

● Monochromatic excitation

● Monochromatic excitationThe emission spectrum of the X-ray tube is monochromatic into the sample by fully focused hyperbolic bending crystal, and the background interference of continuous X-ray tube scattering line is reduced by more than 2 orders of magnitude.

● Focused excitation

Energy focusing further increases the fluorescence intensity of sample elements received by SDD detector.

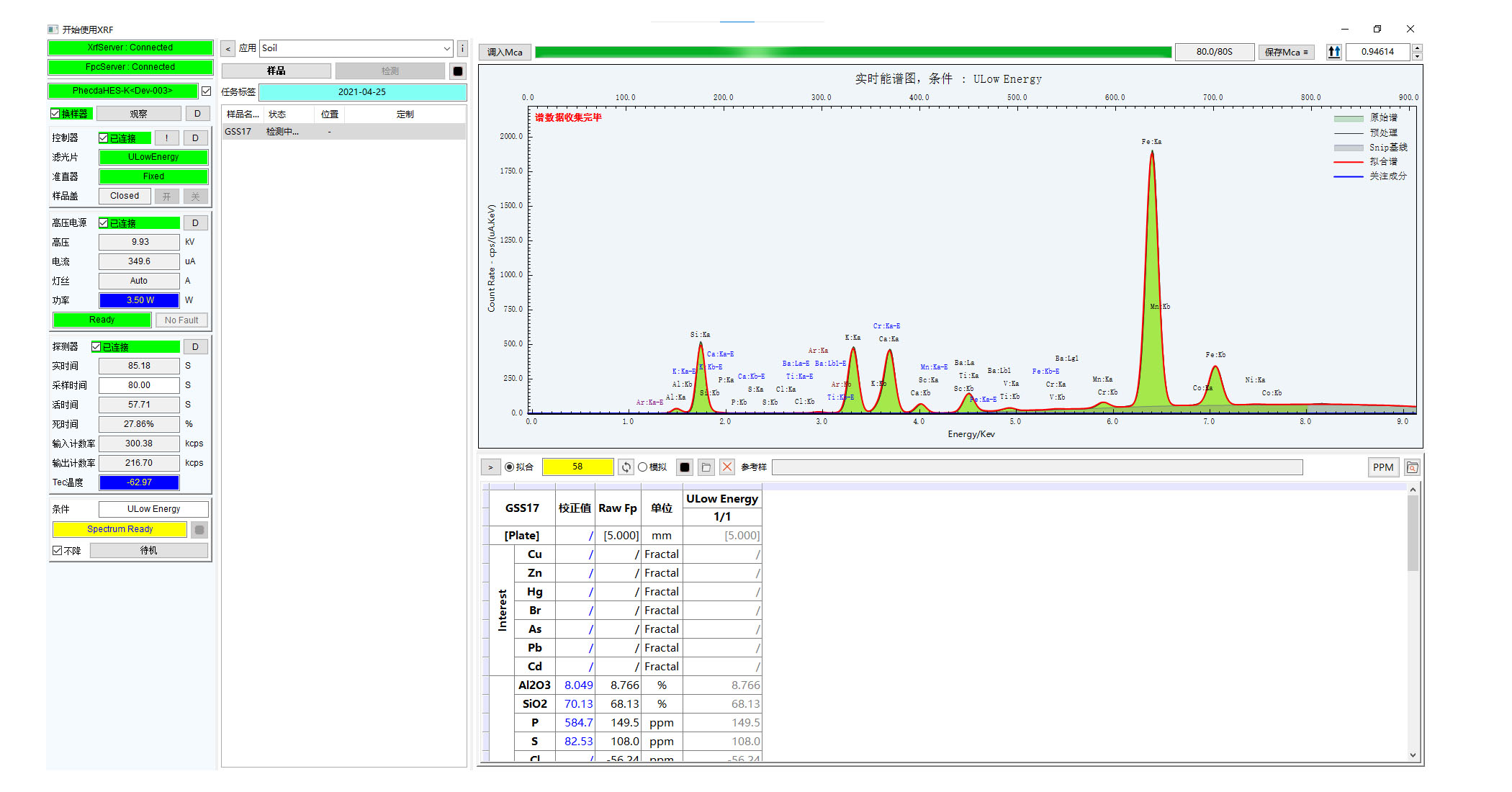

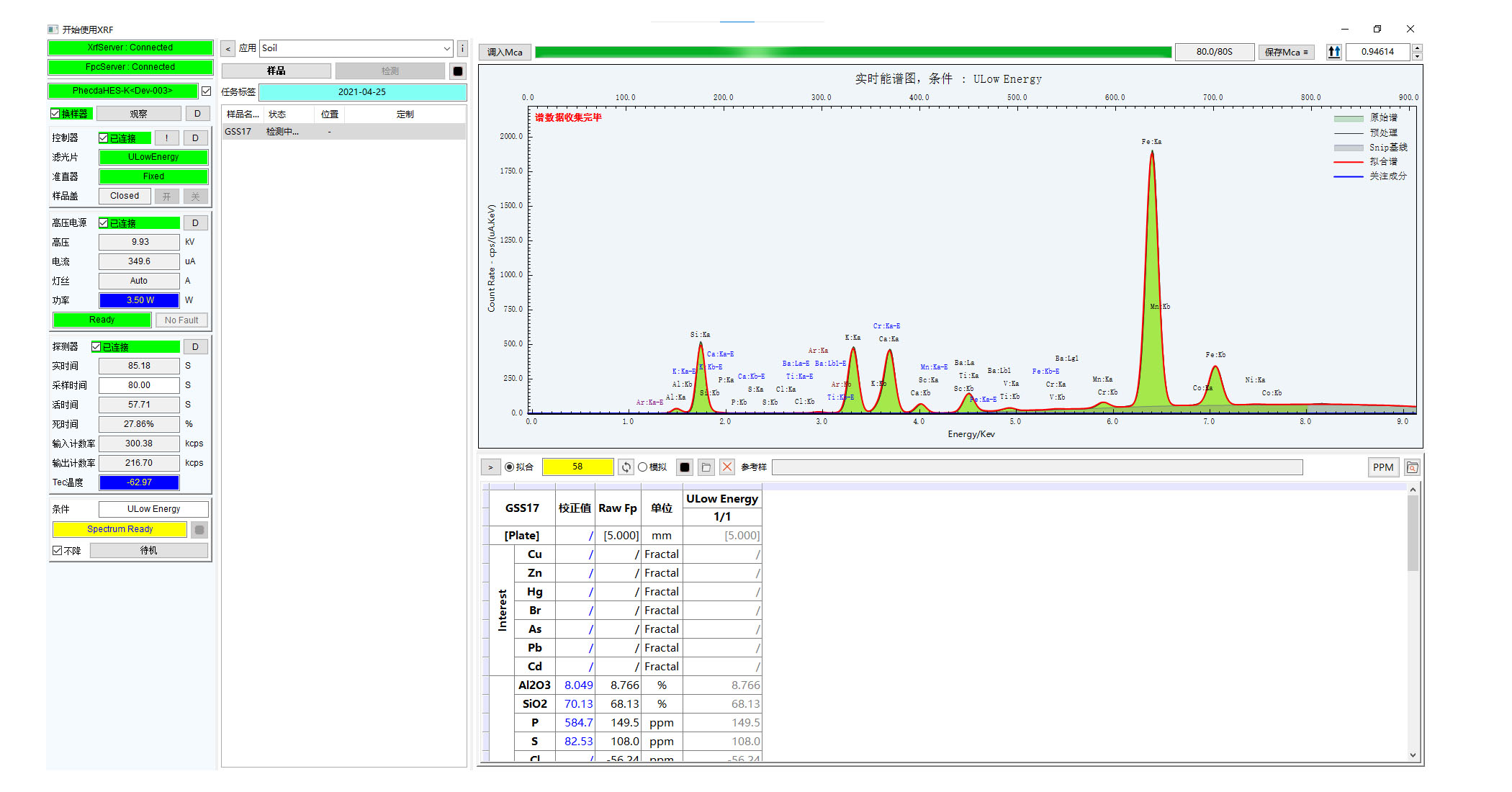

(2)software core technology:Fast Fundamental Parameter Method(Fast FP2.0®)

● Basic parameter library and advanced mathematical model are adopted for the entire X-ray process.

● Basic parameter library and advanced mathematical model are adopted for the entire X-ray process.

● Using a small number of standard samples can further improve the quantitative accuracy of elements.

● Solve the problem of quantitative analysis of elements without standard samples.

Performance parameters

(1)Analysis Range

● Rare earth elements (or oxides)

Lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), Promethium (Pm), samarium (Sm), europium (Eu), gadolinium (Gd), terbium (Tb), Dysprosium (Dy), Holmium (Ho), erbium (Er), thum (Tm), ytterbium (Yb), lutetium (Lu), scandium (Sc), yttrium (Y)

● Inorganic elements and oxides

MgO; Al2O3; SiO2; P2O5; S; Cl; K2O; CaO; TiO2; MnO; Fe2O3; CuO; ZnO; Th; Pb; Cs2O; Rb2O etc.

(2)Content Range

● Detection limit of rare earth elements:

1.0~3.0mg/kg (Note: the detection limit of different rare earth elements is slightly different)

● Content range of rare earth elements

3.0mg/kg~99.99%

● Rare earth types

rare earth minerals, rare earth concentrates, rare earth products, etc

(3)Repeatability

Table 1 Summary of precision data of light rare earth elements

Unit:mg/kg

| Sample Name |

Number of measurements |

La2O3 |

CeO2 |

Pr6O11 |

Nd2O3 |

Sm2O3 |

Gd2O3 |

| GBW07160 |

1 |

112 |

29.4 |

40.0 |

238 |

123 |

239 |

| 2 |

130 |

31.4 |

47.6 |

279 |

138 |

264 |

| 3 |

127 |

34.3 |

46.2 |

274 |

142 |

251 |

| 4 |

148 |

40.9 |

48.0 |

310 |

143 |

276 |

| 5 |

121 |

36.2 |

45.5 |

276 |

134 |

234 |

| 6 |

138 |

39.1 |

45.7 |

291 |

149 |

284 |

| 7 |

120 |

32.4 |

42.5 |

254 |

131 |

251 |

| Standard value(mg/kg) |

111 |

34.8 |

45 |

220 |

150 |

270 |

| Average value(mg/kg) |

128 |

34.8 |

45.1 |

275 |

137 |

257 |

| Standard deviation |

12.14 |

4.17 |

2.87 |

23.2 |

8.7 |

18.5 |

| Relative standard deviation (%) |

9% |

12% |

6% |

8% |

6% |

7% |

Table 2 Summary of precision data for heavy rare earth elements

Unit:mg/kg

| Sample Name |

Number of measurements |

Tb4O7 |

Dy2O3 |

Ho2O3 |

Er2O3 |

Tm2O3 |

Yb2O3 |

Lu2O3 |

Y2O3 |

Sc2O3 |

| GBW07160 |

1 |

47.9 |

313 |

75.8 |

227 |

38.8 |

215 |

29.7 |

2995 |

9.1 |

| 2 |

49.2 |

353 |

68.4 |

237 |

33.6 |

215 |

27.7 |

3002 |

8.0 |

| 3 |

43.6 |

330 |

63.9 |

222 |

31.9 |

218 |

28.8 |

3012 |

8.9 |

| 4 |

45.9 |

327 |

82.0 |

227 |

31.1 |

221 |

28.1 |

2998 |

8.7 |

| 5 |

45.8 |

310 |

63.4 |

205 |

32.3 |

215 |

32.7 |

3007 |

8.1 |

| 6 |

46.2 |

317 |

80.7 |

219 |

31.4 |

219 |

35.1 |

2993 |

9.8 |

| 7 |

45.6 |

326 |

78.0 |

217 |

31.5 |

220 |

31.8 |

2993 |

8.2 |

| Standard value (mg/kg) |

57.7 |

360 |

75 |

220 |

31.6 |

220 |

30.4 |

3030 |

8.9 |

| Average value (mg/kg) |

46.3 |

325.0 |

73.2 |

222 |

32.9 |

218 |

30.6 |

3000 |

8.7 |

| Standard deviation |

1.79 |

14.45 |

7.84 |

9.96 |

2.71 |

2.55 |

2.73 |

7.35 |

0.64 |

| Relative standard deviation (%) |

4% |

4% |

11% |

4% |

8% |

1% |

9% |

0.5% |

7% |

(4)Analysis accuracy

By analyzing the four standard samples GBW07158-GBW07161 of rare earth ore composition analysis standard materials, the analysis accuracy of the total amount of rare earth oxides was obtained as follows:

| Standard sample |

GBW 07158 |

GBW 07159 |

GBW 07160 |

GBW 07161 |

| Standard value (%) |

0.092 |

0.085 |

0.486 |

0.784 |

| Method test value(%) |

0.089 |

0.090 |

0.499 |

0.732 |

| Standard deviation |

-3.3% |

5.9% |

2.7% |

-5.4% |

Features and advantages

Simple sample processing

Simple sample processing

The rare earth minerals are uniformly treated to more than 80 mesh by crushing and grinding, and the rare earth products have a test plane of 1cm².

Fast analysis

Fast analysis

The sample analysis time is less than 10 minutes.

Wide application range

Wide application range

Analysis and application methods can be quickly established for different types of rare earth minerals, rare earth concentrates, rare earth products, and high-purity rare earths.

Project presentation

Original statement:

This article is the original work of ancoren company except for the quotation. If it is forwarded and quoted, the source must be indicated, otherwise it may involve infringement. For more detailed technical information, please consult the staff of Ancoren.