Application Overview

Slag is a by-product of the blast furnace smelting process, mainly composed of oxides such as CaO, SiO2, Al2O3, MgO, MnO, Fe2O3 and a small amount of sulfide. As a type of solid waste, the content of harmful elements such as S, Cl, Cr, As, Pb, Hg, Cd, etc. is controlled. Due to the variety of slag and the complex matrix, a fast, accurate and widely adaptable Element content detection methods have received more and more attention.

The single-wavelength excitation-energy dispersive X-ray fluorescence spectrometer developed by Ankehuisheng combined with the fast basic parameter method can effectively improve the elemental analysis accuracy of slag samples.

Performance Data

(1)Element range

| Main Elements |

MgO、Al2O3、CaO、SiO2、Fe2O3、SO3 |

| Trace Elements |

F、Cl、Cu、Mn、Cr、As、Hg、Zn、Sn、Sb、Pb、Ni、Cd、Tl、Mo、Co、V etc. |

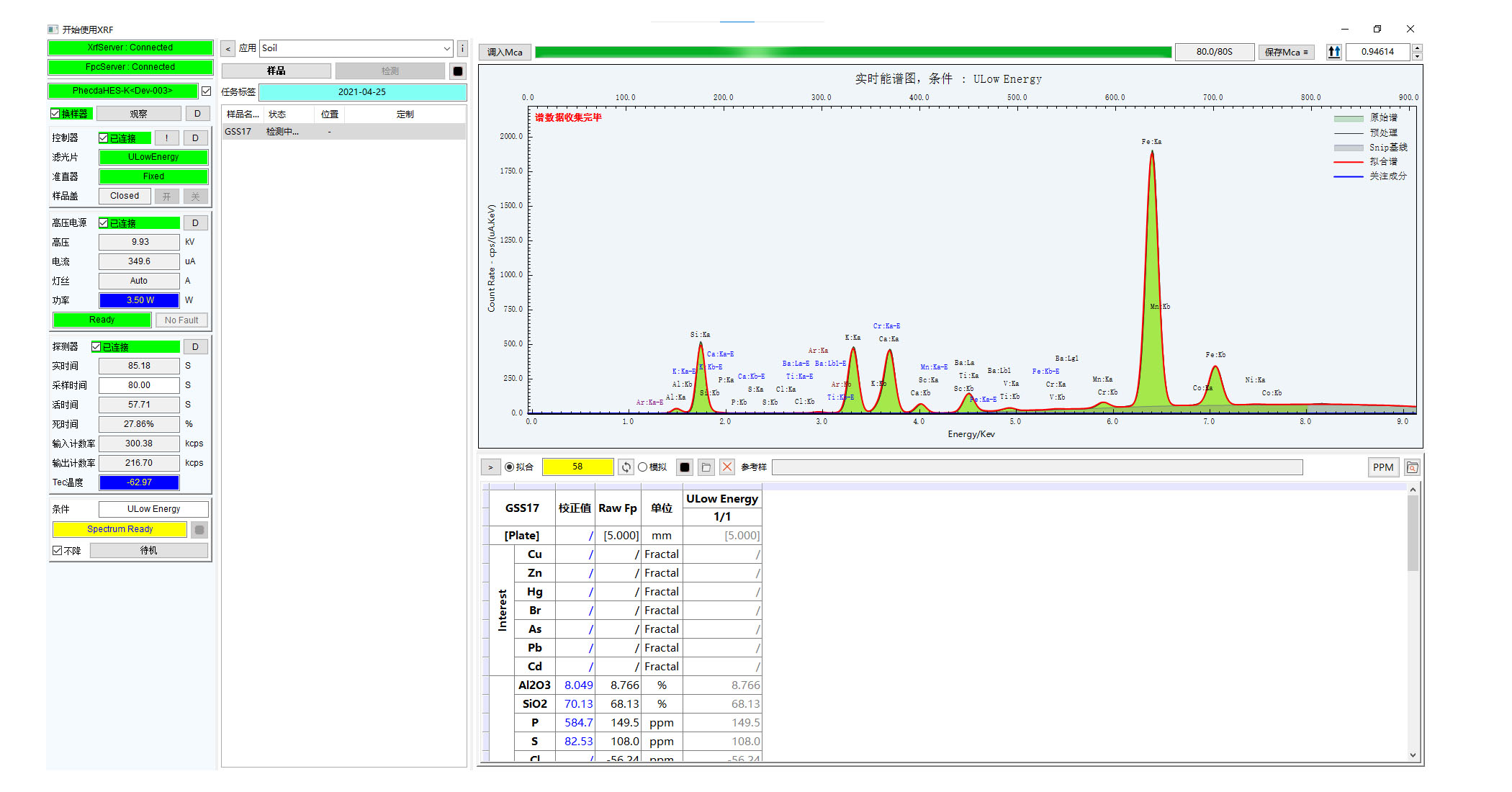

(2) Linearity

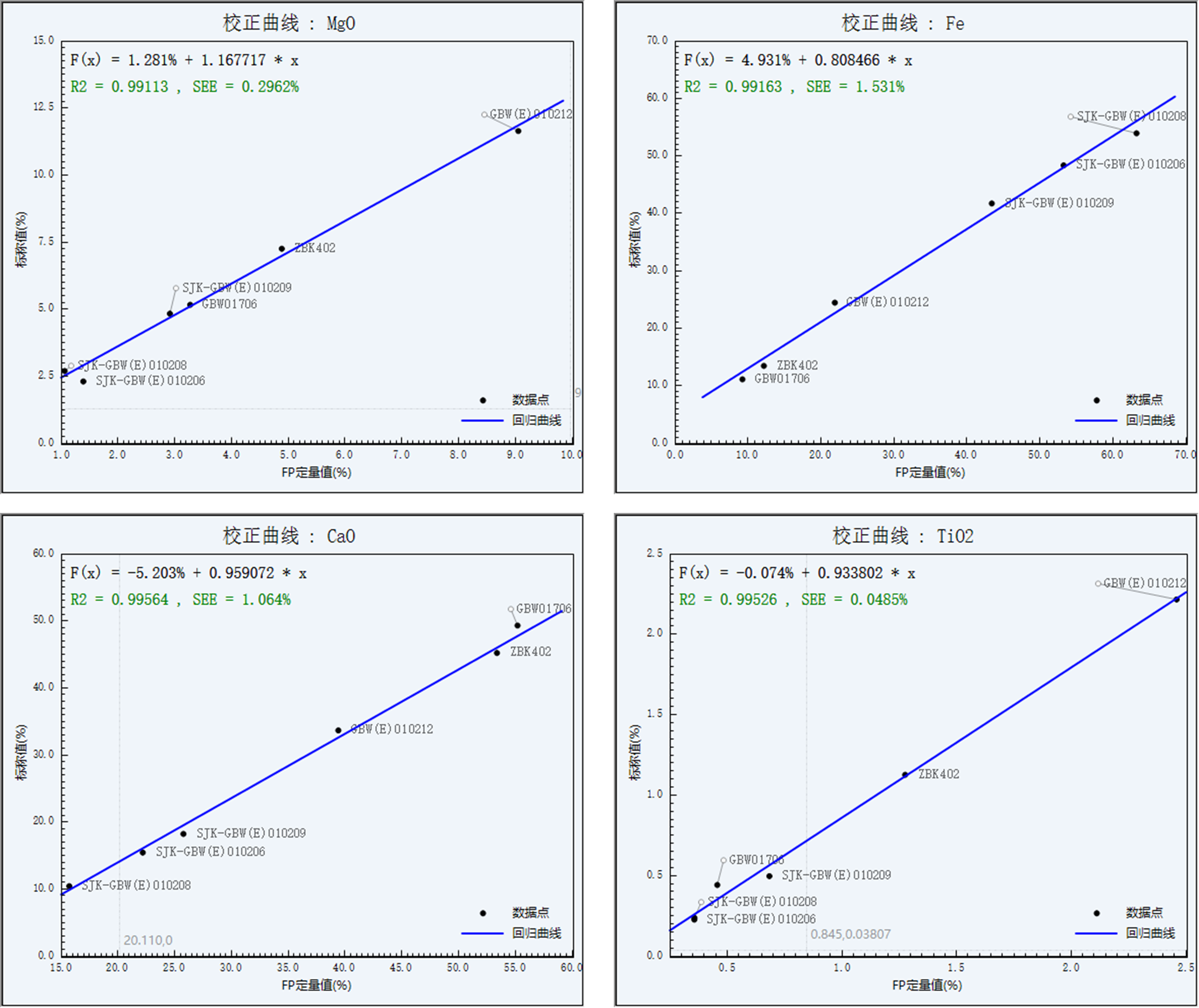

Calibration curve of some major elements in slag

Calibration curve of some major elements in slag

(2)Accuracy

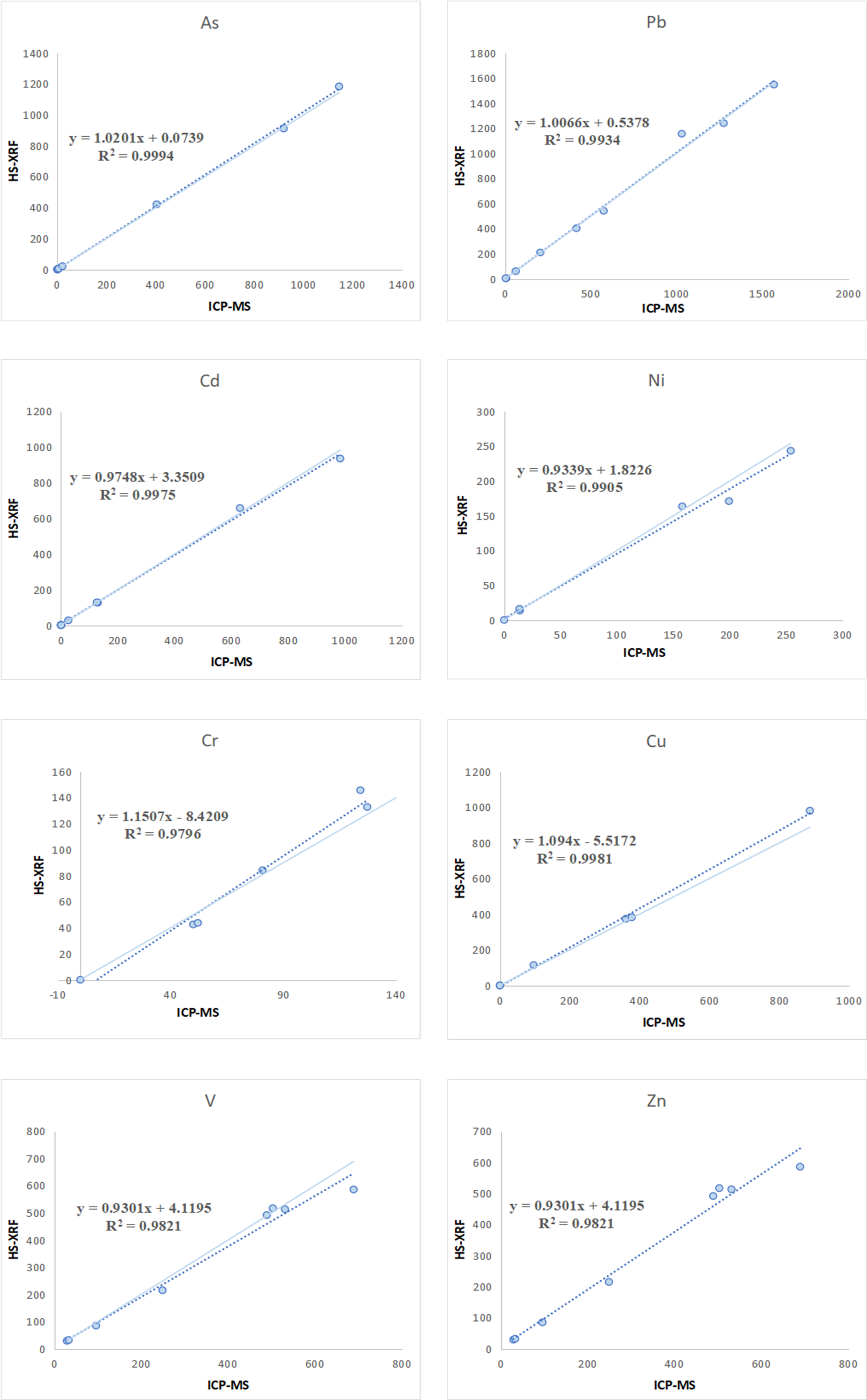

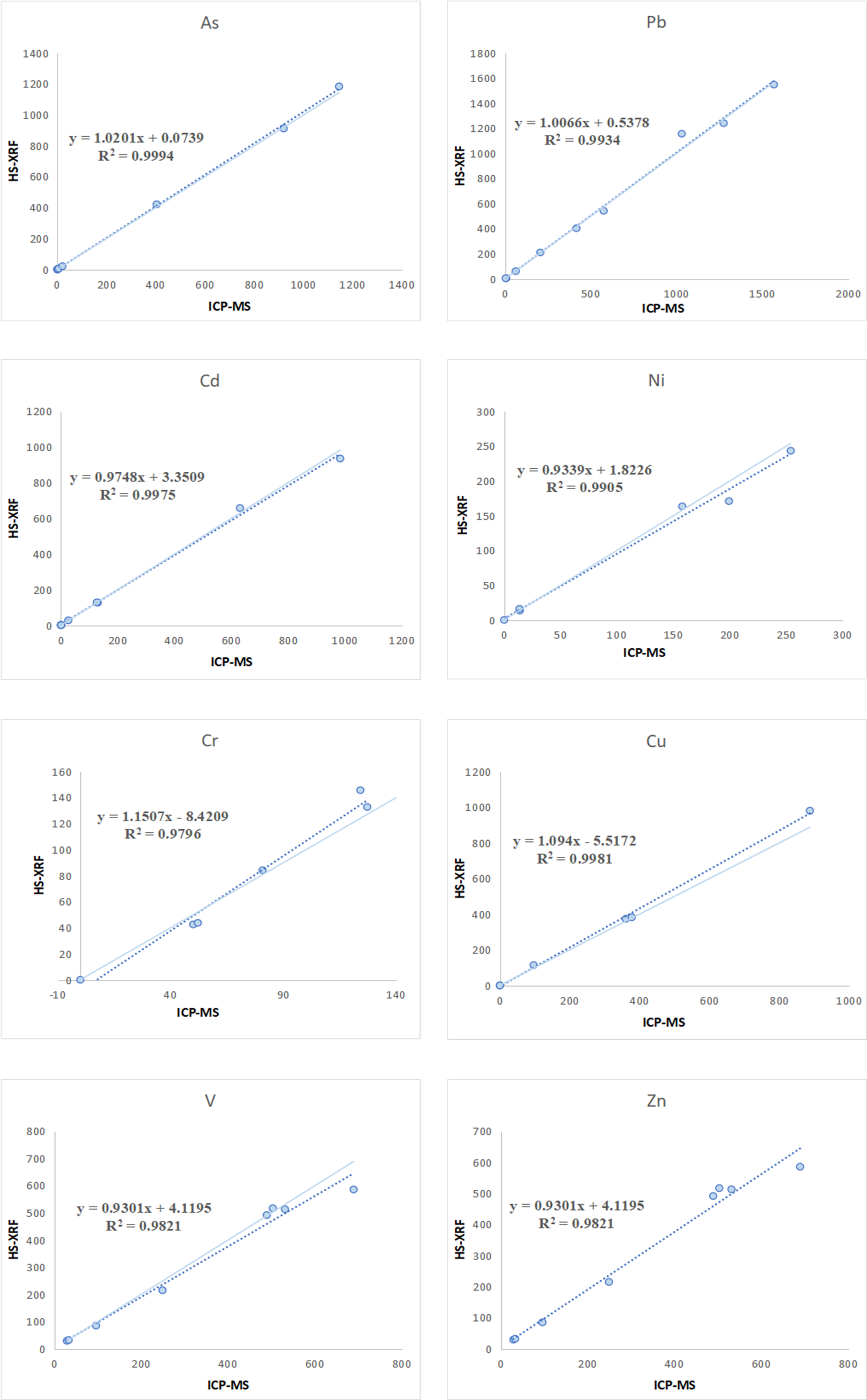

Consistency comparison of slag trace element test values and ICP-MS values

The linear relationship between the test values of HS XRF and Fast FP2.0 and the test values of ICP MS is close to the complete line of Y=X (45°angle), indicating the actual sample test results High consistency with the ICP MS method.

Features and advantages

Wide range of adaptation

Wide range of adaptation

It is suitable for various types of slag produced by mineral smelting.

Simple sample preparation

Simple sample preparation

The sample is crushed and ground to more than 80 mesh, and it can be put into a cup.

Wide element range

Wide element range

From major elements to trace elements, dozens of elements can been analyzed at once.

simple to calibrate

simple to calibrate

Fast FP2.0 requires only a fewer number of samples to build a calibration curve.

Method principle

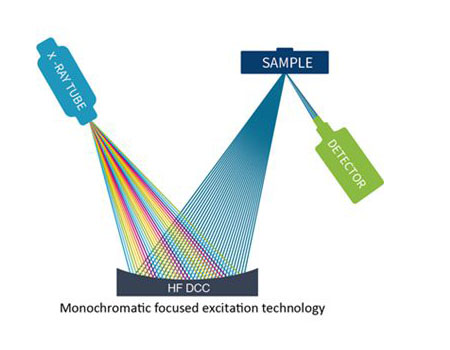

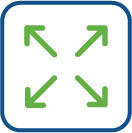

(1)Monochromatic focusing excitation technology

● It makes that element detection sensitivity has been improved by 2 orders of magnitude.

● Realizing the ability to analyze trace metal elements.

(Patent No:ZL 2015 1 0567341.1)

(2)Fast Fundamental Parameters(Fast FP®)

We uses the fundamental parameter library and a series of advanced mathematical models to solve the uncertainty and analysis error caused by various effects of XRF, realizing the quantitative analysis of various samples without standard samples.

We uses the fundamental parameter library and a series of advanced mathematical models to solve the uncertainty and analysis error caused by various effects of XRF, realizing the quantitative analysis of various samples without standard samples.

From major elements to trace elements, dozens of elements can been analyzed at once.

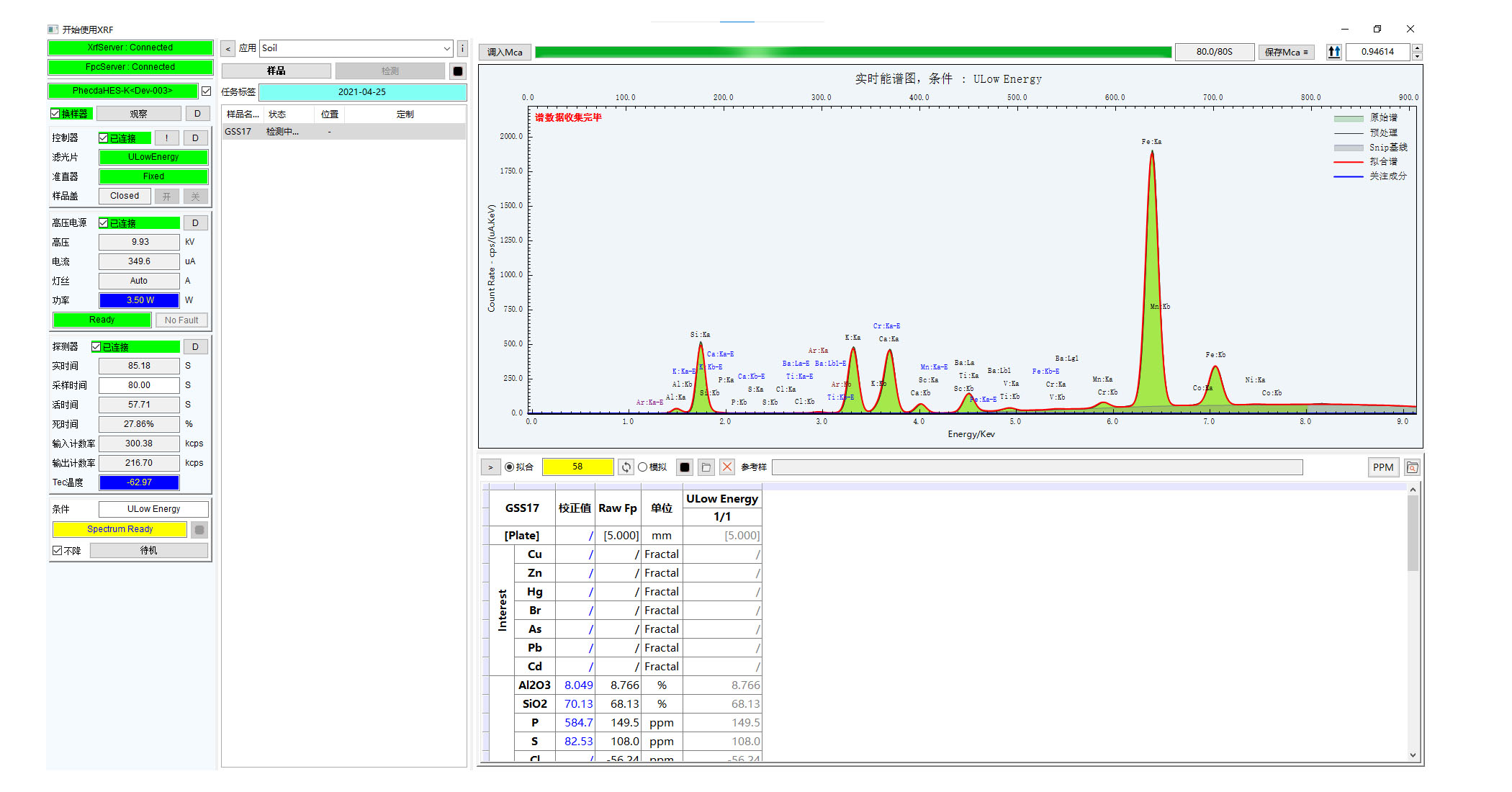

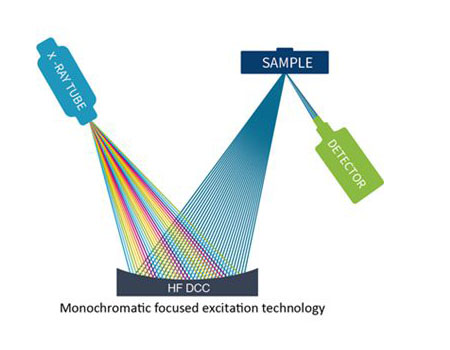

Solution show

Original statement:

Original statement:

Wide range of adaptation

Wide range of adaptation Simple sample preparation

Simple sample preparation Wide element range

Wide element range