Application Overview

Precious metal (gold, silver, platinum, palladium, rhodium, etc.) materials have special use value, as well as investment value that preserves and continues to appreciate in value, and are the object of capital pursuit. In recent years, with the maturity of precious metal recovery technology, the discovery and recovery of precious metals in electroplating and smelting waste, electronic materials and spent catalysts has become a new industry with low investment costs and high returns. However, it is difficult to detect traces of precious metals with recovery value, and there is a lack of analytical methods to quickly detect the elemental content of precious metals, and there are problems such as high cost and slow analysis of samples, which make it difficult for "treasure hunters".

Traditional X-ray fluorescence spectrometers (XRF) for precious metal content analysis are only capable of detecting high precious metal content, but most materials with recovery value usually have precious metal content of 1-100mg/kg. Fast FP can be used for the rapid detection of trace precious metals, with low detection limits, fast analysis, simple sample preparation and low analysis costs, making it a "pair of eyes" for the discovery of precious metals. HS XRF is also capable of trace element analysis, so that high-purity precious metal samples can be analysed, and the high-performance Fast FP method is capable of analysing precious metal plating thicknesses.

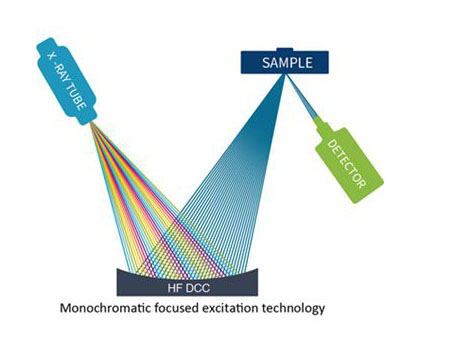

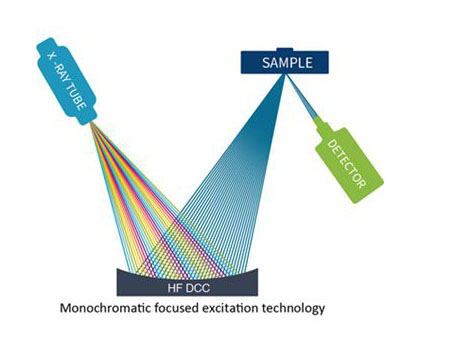

● 2 orders of magnitude improvement in elemental detection sensitivity

● HS XRF enables analysis of trace metal elements

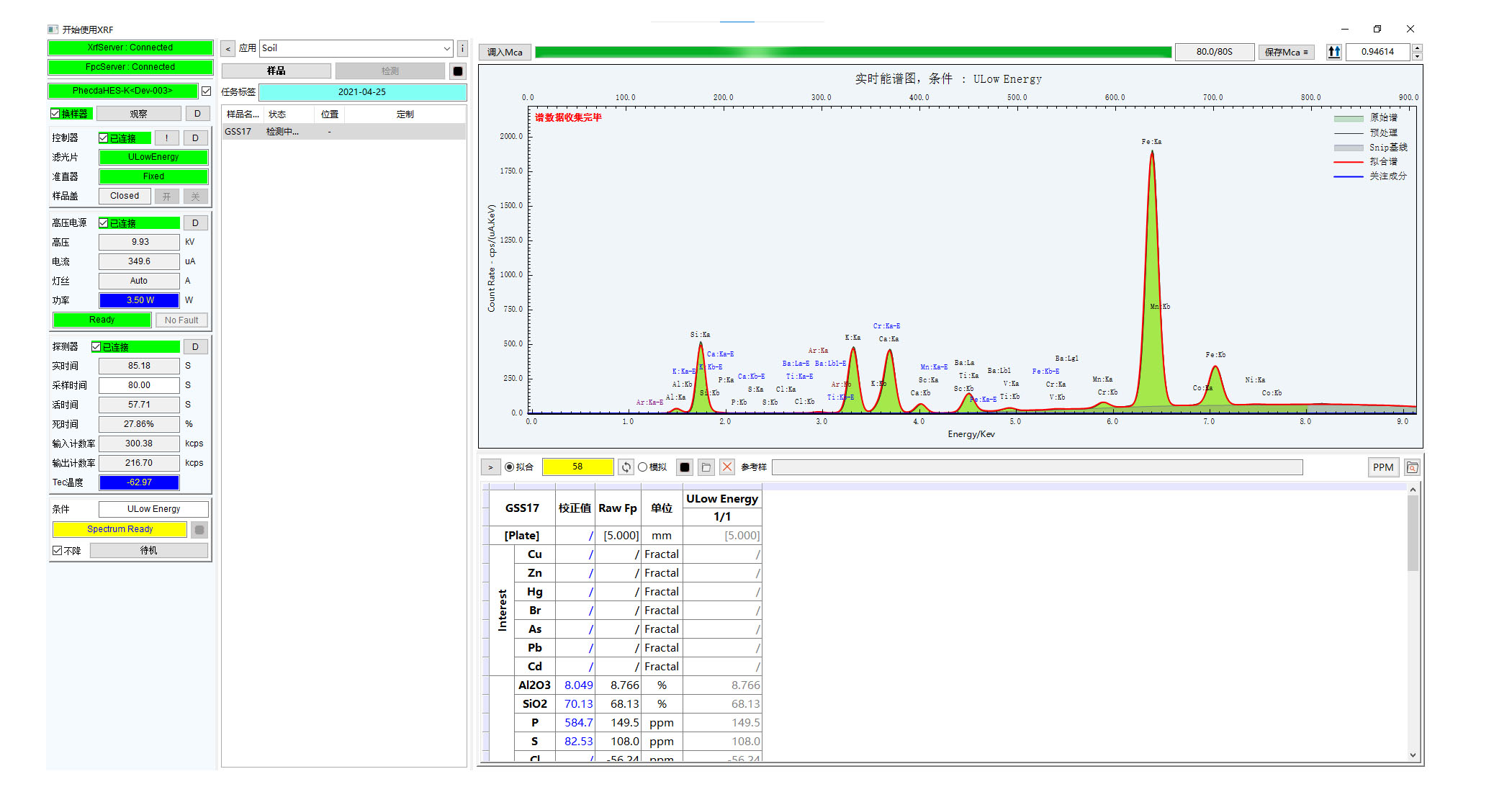

(2)Fast fundamental parameters method(Fast FP®))

● Using a library of fundamental parameters and a series of advanced mathematical models

● Using a library of fundamental parameters and a series of advanced mathematical models

● Resolving uncertainties and analytical errors associated with various XRF effects

● Enables quantitative analysis of all types of samples without standard samples

Performance data

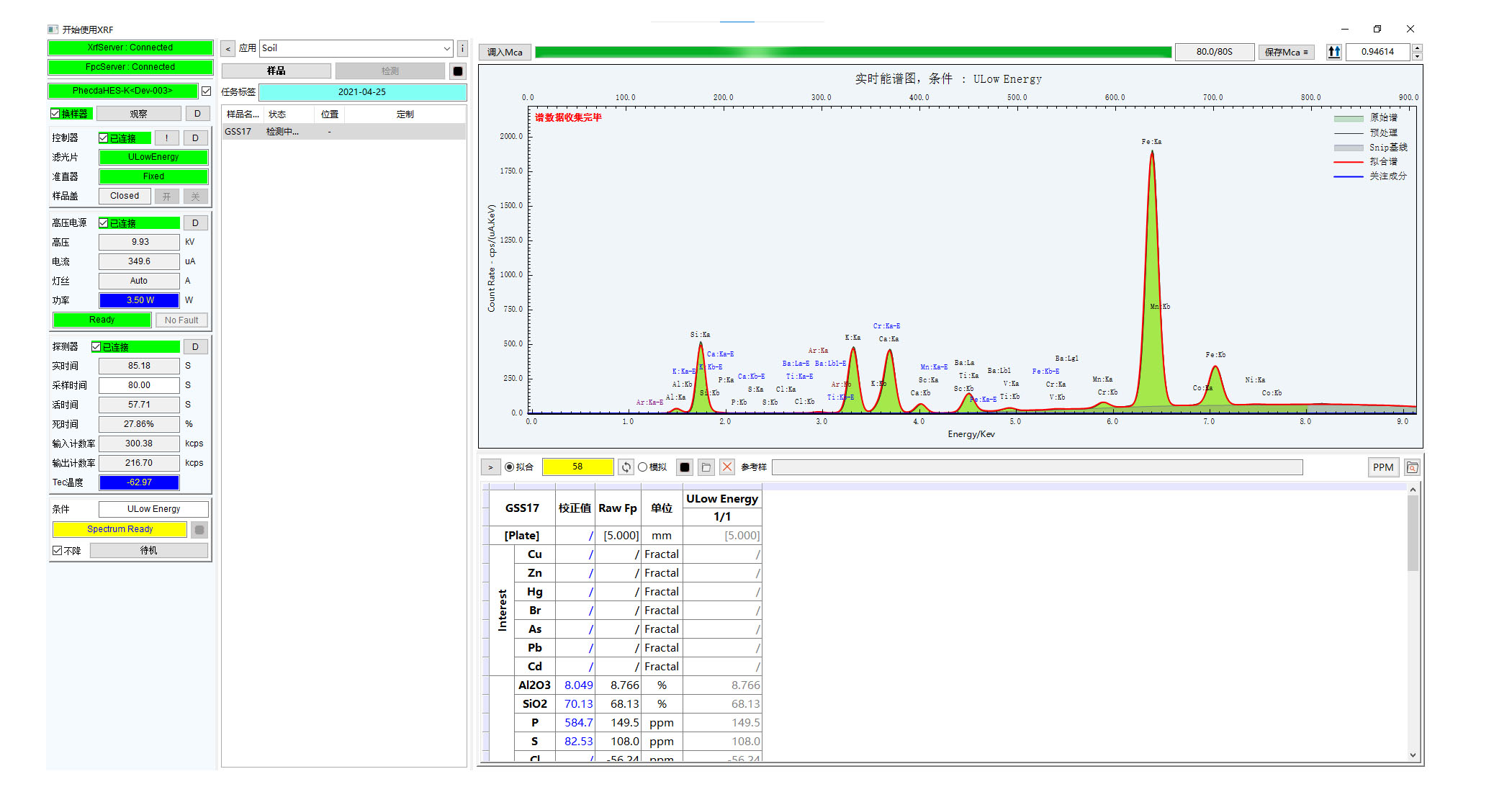

(1)Detection limit

Table 1 Summary of detection limits for precious metals

Unit: mg/kg

| Precious Metals |

Gold (Au) |

Silver (Ag) |

Platinum (Pt) |

Palladium (Pd) |

Rhodium (Rh) |

| Detection limit |

0.7 |

0.3 |

1.0 |

0.3 |

0.3 |

| Quantitative limits |

2.0 |

1.0 |

3.0 |

1.0 |

1.0 |

Note: Sample testing time 300 seconds

Note: The detection limits for precious metals are influenced by the content of other elements in the sample and are measured in the absence of strong interfering elements in the sample.

(2)Repeatability

Table 2 Summary of precious metal precision

Unit: mg/kg

| Precious metal elements |

Platinum (Pt) |

Palladium (Pd) |

| Test 1 |

4.98 |

1.85 |

| Test 2 |

5.14 |

1.75 |

| Test 3 |

5.52 |

1.61 |

| Test 4 |

6.11 |

1.57 |

| Test 5 |

4.88 |

1.65 |

| Test 6 |

5.39 |

1.96 |

| Test 7 |

6.48 |

1.75 |

| Standard values |

5.70 |

1.67 |

| Average |

5.50 |

1.73 |

| RSD |

11% |

8% |

Description

The test sample is a standard substance for the analysis of the geochemical composition of platinum group elements GBW07342. Sample test time of 450 seconds.

(3)Accuracy

Table 3 Precious metals accuracy summary

| Precious metal elements |

Content range (mg/kg) |

Relative Deviation (RD) |

Gold (Au), Platinum (Pt) |

3~10 |

<25% |

| 10~100 |

<15% |

| >100 |

<10% |

Silver (Ag), Palladium (Pd)

Rhodium (Rh) |

2~10 |

<25% |

| 10~100 |

<15% |

| >100 |

<10% |

Note:

Accuracy is influenced by sample type, preparation method, content of interfering elements, etc. Calibration with standard substances will further improve accuracy.

(4)High purity precious metal analysis

Buy gold jewellery marked 999.9 gold, gold flakes (≥99.5% gold) and ordinary gold flakes (≥99% gold) and test them for impurities and their content respectively. The results of the tests are as follows:

Table 4 Comparison of test results for different gold content samples

Unit: mg/kg

| Sample name |

Au |

Cu |

Zn |

Ga |

Pb |

Mn |

Ni |

Cr |

Fe |

Ag |

Cd |

| Gold jewellery |

99.96% |

17.31 |

113.1 |

170.8 |

16.50 |

21.36 |

12.90 |

N.D |

N.D. |

27.29 |

115.3 |

| Gold flakes |

99.86% |

39.66 |

457.5 |

83.92 |

N.D |

5.25 |

N.D. |

74.9 |

664.7 |

5.14 |

N.D |

| Gold flakes |

99.58% |

N.D |

N.D |

61.48 |

90.40 |

368.6 |

70.94 |

649.7 |

0.2743% |

97.88 |

123.3 |

Note: N.D indicates non-detect.

(5)Precious metal plating thickness analysis

For different metal substrates plated with precious metals, the thickness of the precious metal plating can be accurately determined as follows.

Sample 1: Gold plating on a metallic copper substrate

| Type of plated precious metal |

Actual thickness |

Test thickness |

| Gold (Au) |

0.53μm |

0.53μm |

| Gold (Au) |

2.10μm |

2.07μm |

| Gold (Au) |

4.83μm |

4.72μm |

| Gold (Au) |

9.64μm |

9.43μm |

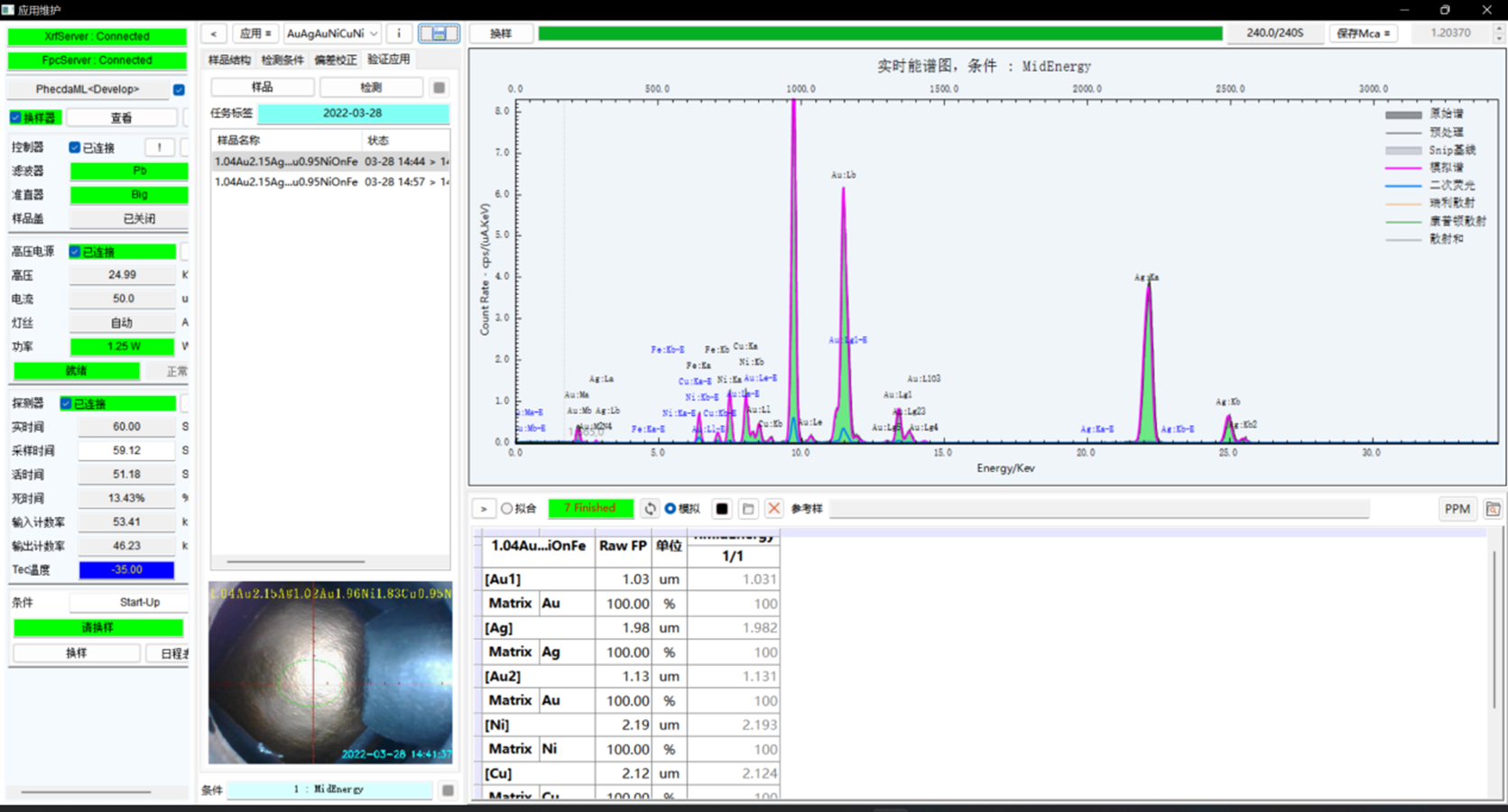

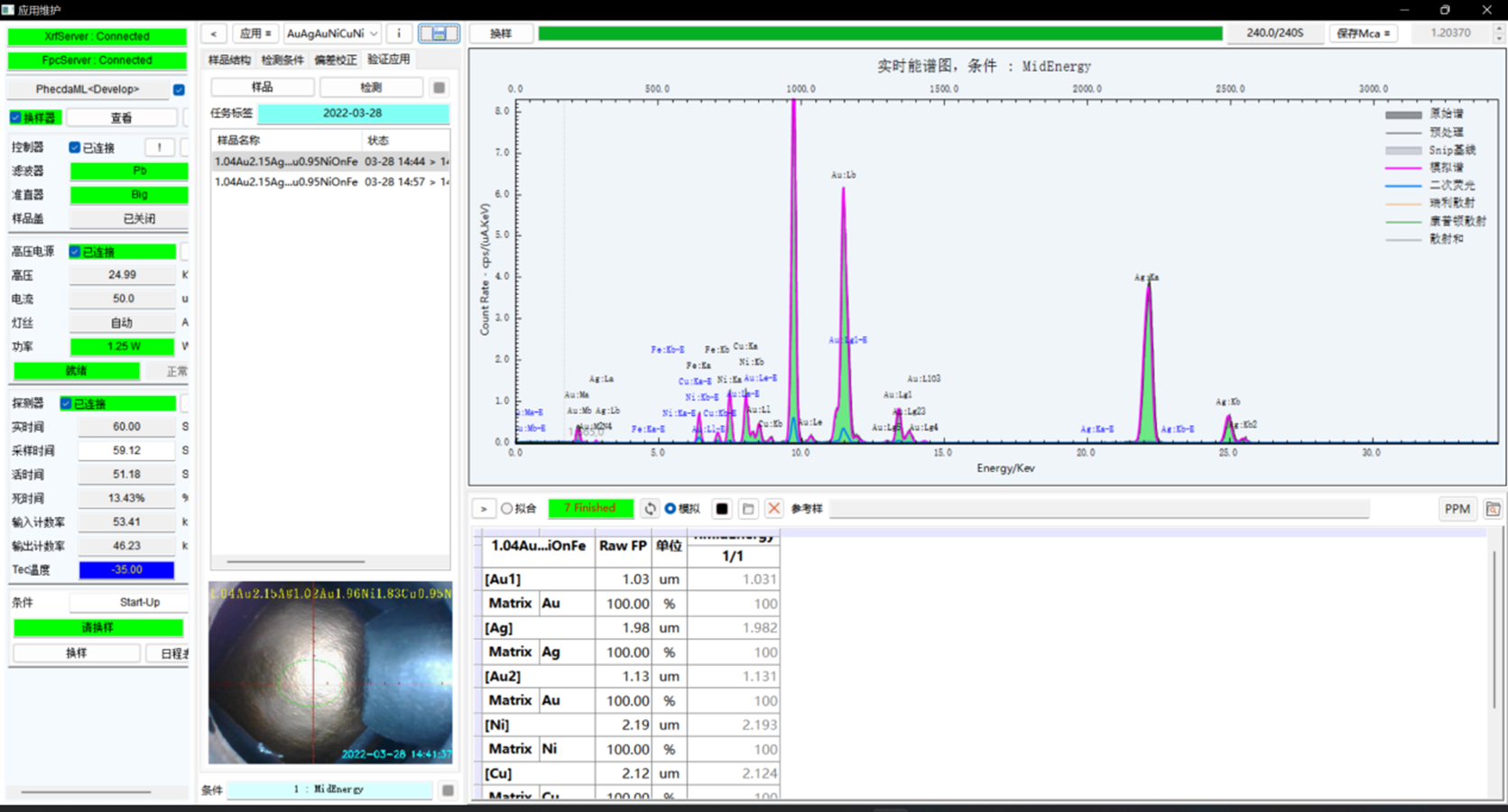

Complex Sample 2: Multiple layers of metal on a metallic iron substrate plated from bottom to top with nickel-copper-nickel-gold-silver-gold, with the following test results.

| Type of plating metal |

Actual thickness |

Test thickness |

| Gold (Au) 1 |

1.04μm |

1.03μm |

| Silver (Ag) |

2.15μm |

1.98μm |

| Gold(Au)2 |

1.02μm |

1.13μm |

| Nickel (Ni)1 |

1.96μm |

2.19μm |

| Copper (Cu) |

1.83μm |

2.12μm |

| Nickel (Ni)2 |

0.95μm |

1.23μm |

Example of a spectrum (enlargement of the test surface of the sample is shown in the lower left).

Example of a spectrum (enlargement of the test surface of the sample is shown in the lower left).

Application features

Fast detection

Simultaneous analysis of precious metals (gold, silver, platinum, palladium, rhodium, etc.) in 5 to 10 minutes for one sample.

Fast detection

Simultaneous analysis of precious metals (gold, silver, platinum, palladium, rhodium, etc.) in 5 to 10 minutes for one sample.

Low detection limit

Single wavelength focused excitation technique pioneering the reduction of precious metal content detection limits to <1mg/kg levels.

Low detection limit

Single wavelength focused excitation technique pioneering the reduction of precious metal content detection limits to <1mg/kg levels.

Simple sample preparation

The ability to test solid, powder, liquid and paste samples, providing sample preparation equipment and methods.

Simple sample preparation

The ability to test solid, powder, liquid and paste samples, providing sample preparation equipment and methods.

On-site testing

The instrument is portable and can be used in any location and environment to complete on-site testing of materials for precious metal content.

On-site testing

The instrument is portable and can be used in any location and environment to complete on-site testing of materials for precious metal content.

Low testing costs

Cost of analysis of a single sample of ¥10 or less.

Low testing costs

Cost of analysis of a single sample of ¥10 or less.

Original statement:

This article is the original work of ancoren company except for the quotation. If it is forwarded and quoted, the source must be indicated, otherwise it may involve infringement. For more detailed technical information, please consult the staff of Ancoren.

Fast detection

Fast detection Low detection limit

Low detection limit Simple sample preparation

Simple sample preparation On-site testing

On-site testing Low testing costs

Low testing costs