Application overview

80% of my country's iron ore demand comes from imports. In 2020, iron ore imports reached a record 1.17 billion tons. With China's ban on the import of "foreign garbage", if the bulk imported iron ore is mixed with various solid wastes such as waste residue and tailing residue, it will bring new risks and challenges to the customs supervision.

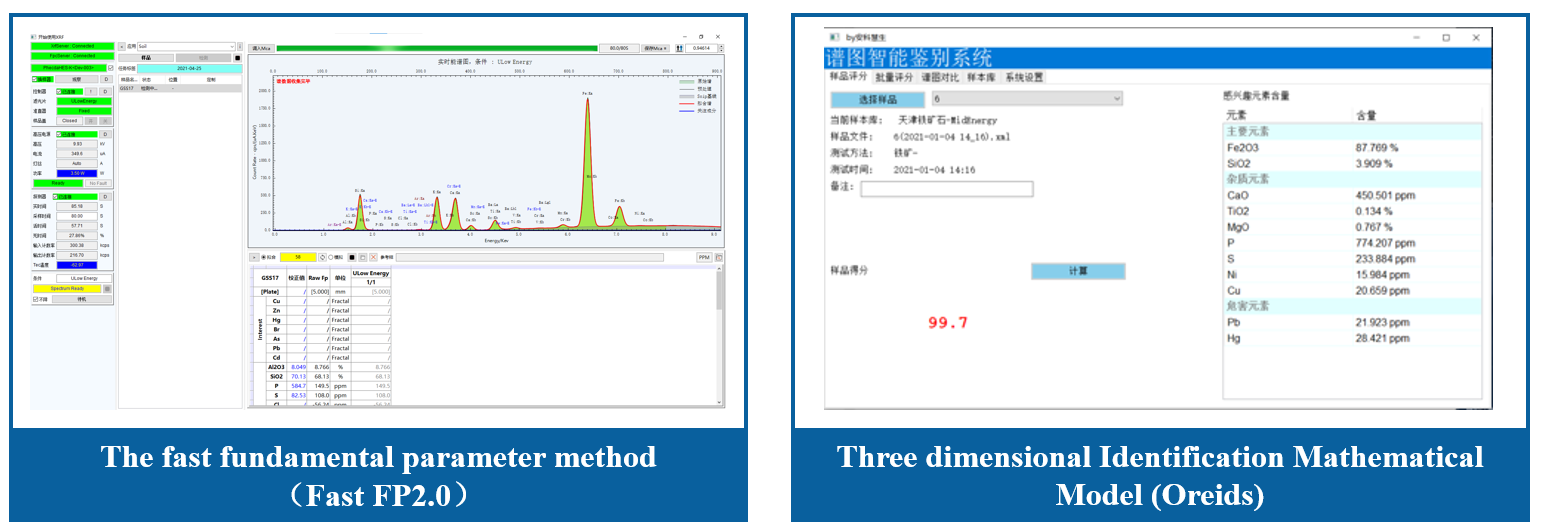

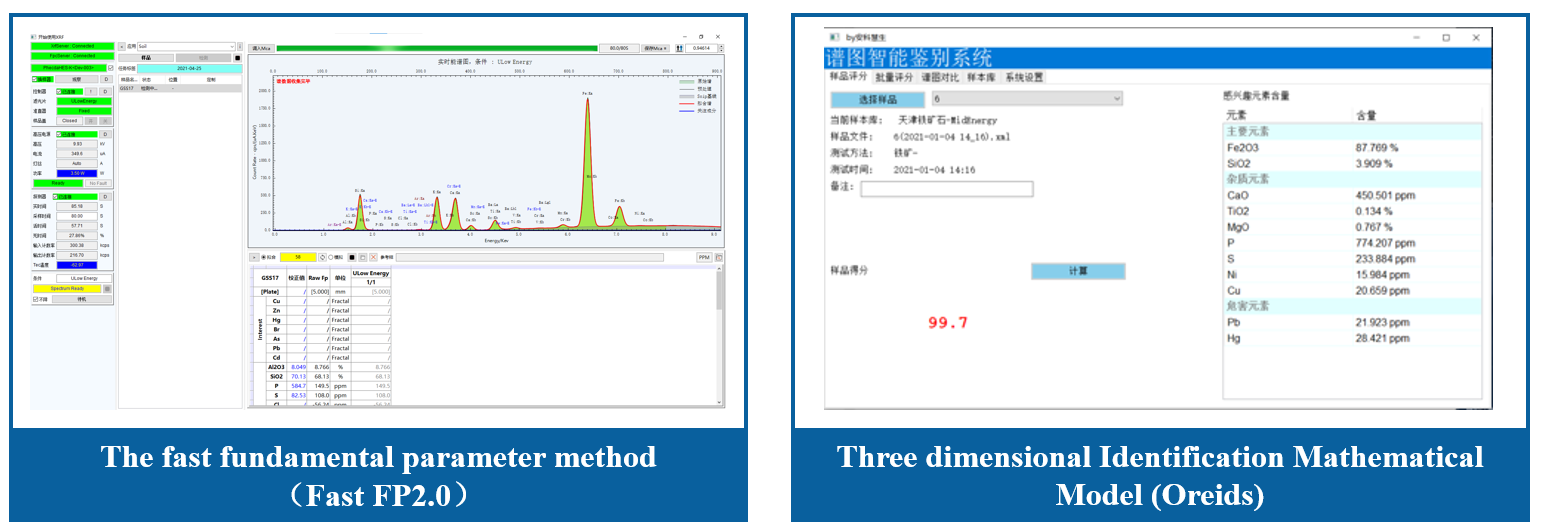

In addition to the grade of iron ore, it is necessary to fully consider its material composition and utilization value. Iron ore samples are different in phase composition and element content from other materials. Iron Ore Identification System (OreIDs) uses single wavelength X-ray fluorescence spectrometry (HS XRF®) to analyze the element content and identify the spectrum of iron ore samples, uses Fast fundamental parameter method (Fast FP®) to get the element content and background composition of iron ore. The similarity of iron ore was determined by spectral database retrieval and component identification algorithm.

Method principle

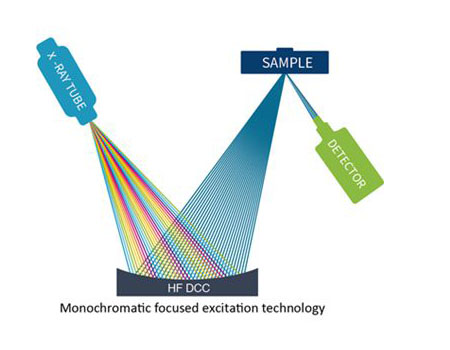

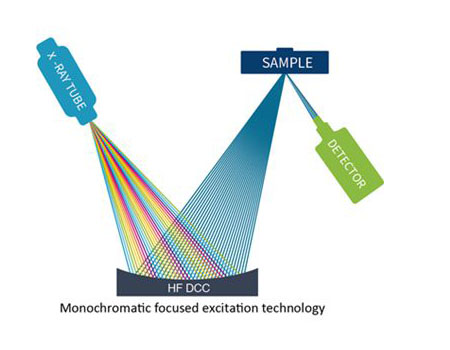

(1)Principle of single wavelength X-ray fluorescence spectrometer

The single-wavelength X-ray fluorescence spectrometer adopts the technology of the fully focused hyperbolic bending crystal. The fully focused hyperbolic bending crystal monochromates the characteristic rays of the target material in the X-ray tube emission spectrum, and focuses the diffraction to one point of the sample, which greatly reduces the interference of the background of continuous scattered rays in the X-ray to the element spectrum of the sample, and improves the element detection signal-to-noise ratio. The detection limit is 1-2 orders of magnitude lower than that of traditional XRF. The single-wavelength X-ray fluorescence spectrometer realizes the detection and analysis of micro-elements and trace-elements.

(2)Fast fundamental parameter method

Fundamental parameter method (FP) is an important technique for XRF quantitative analysis.It establishes a basic parameter library and a series of mathematical models for the well-defined physical phenomena of X-ray fluorescence physics. After large number of calculations, the content of each element in the sample is directly obtained, which solves the complexity and uncertainty of quantitative analysis of XRF matrix effect, inter-element absorption enhancement effect, spectral line overlapping interference, detector effects and so on, and realizes the quantitative analysis of sample elements in the absence of standard samples. The Fast Fundamental Parameter Method (Fast FP) developed by Beijing Ancoren is a comprehensive fundamental parameter method, which is in a leading position in terms of sample adaptability, quantitative accuracy, and scalability.

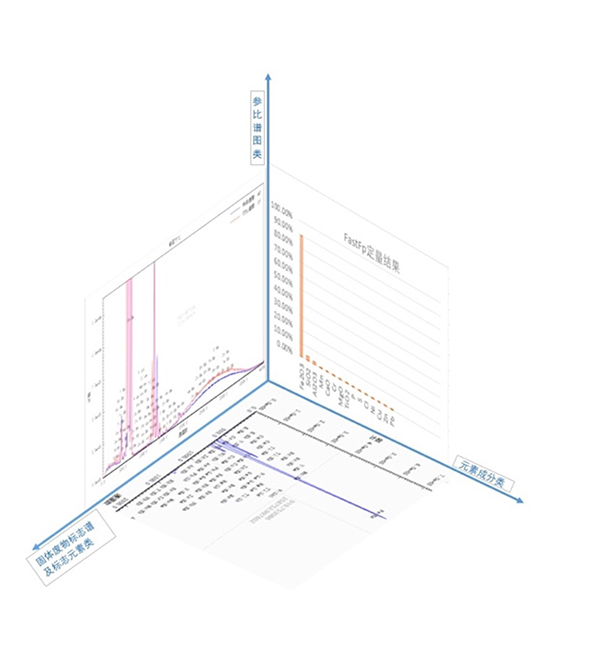

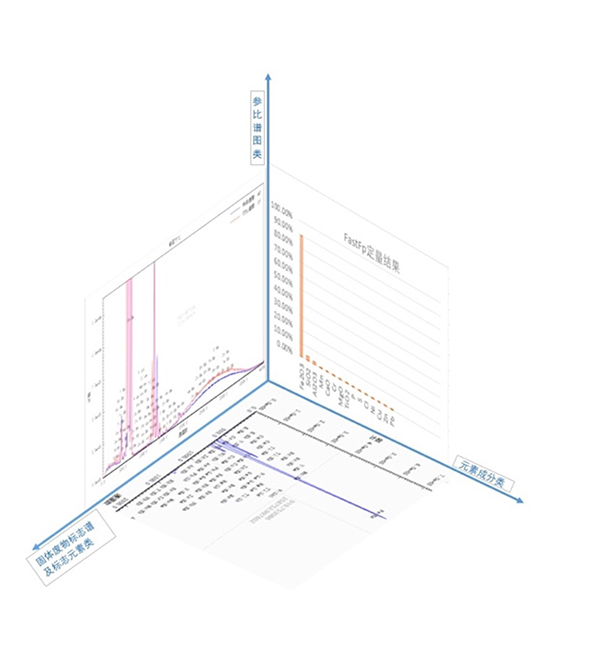

(3)Three-dimensional identification mathematical model OreIDs for iron ore

XRF energy spectrum includes abundant information such as element spectrum, background spectrum, and main element scattering line spectrum, which provides scientific data information for component identification, and can also establish relevant standard spectrum library.

The establishment of three-dimensional identification model, one-dimensional is to establish the iron ore single wavelength X-ray fluorescence spectrum and basic parameter reference database, by scanning a large number of actual iron ore samples and standard iron ore samples to obtain the spectrum, and then analyze the spectrum through clustering algorithm, then establishment of iron ore reference database; two-dimensional is to carry out principal component analysis (PCA) of normal iron ore, and set the main element content range; three-dimensional is to scan and analyze various types of slag, tailings, other Ores and various solid wastes, establish a pseudo-iron ore spectrum and element content library, and perform cluster analysis to obtain a reliable mathematical model.

The Three-dimensional identification mathematical model OreIDs for iron ore has the function of extension and learning, can be extended to other ores identification. By analyzing large number of samples, the algorithm self-learning, and continuously improve its judgment accuracy.

Performance Data

The similarity identification results of Ore identification system OreIDs for iron ore, other ores, solid waste (waste slag, slag, sludge, etc.) are as follows:

| Sample category |

Number of samples |

Similarity interval(0-100%) |

| Iron ore sample |

97 |

91.8-99.7 |

| Iron ore standard sample |

22 |

91.5-99.7 |

| Suspected iron ore |

2 |

69.6-71.6 |

| Other ore samples |

20 |

75.0-46.8 |

| Solid waste samples |

25 |

44.9-74.2 |

The Oreids similarity score was further verified after a certain proportion of iron ore standard sample mixed with ferroalloy slag:

| Sample |

Oreids similarity score |

| Iron ore standard sample ZbK3088 |

99.5 |

| Ferroalloy slag 3#3# |

64.1 |

| Zbk 90%+slag10% |

88.7 |

| Zbk 80%+ slag 20% |

82.5 |

| Zbk 70%+ slag 30% |

78.5 |

| Zbk 60%+ slag 40% |

73.9 |

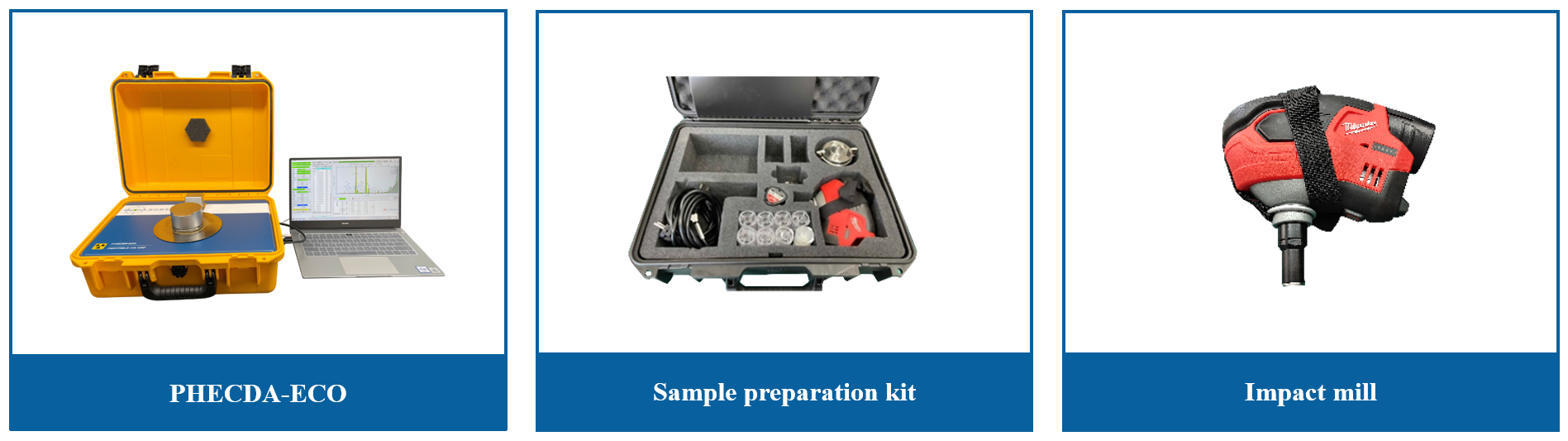

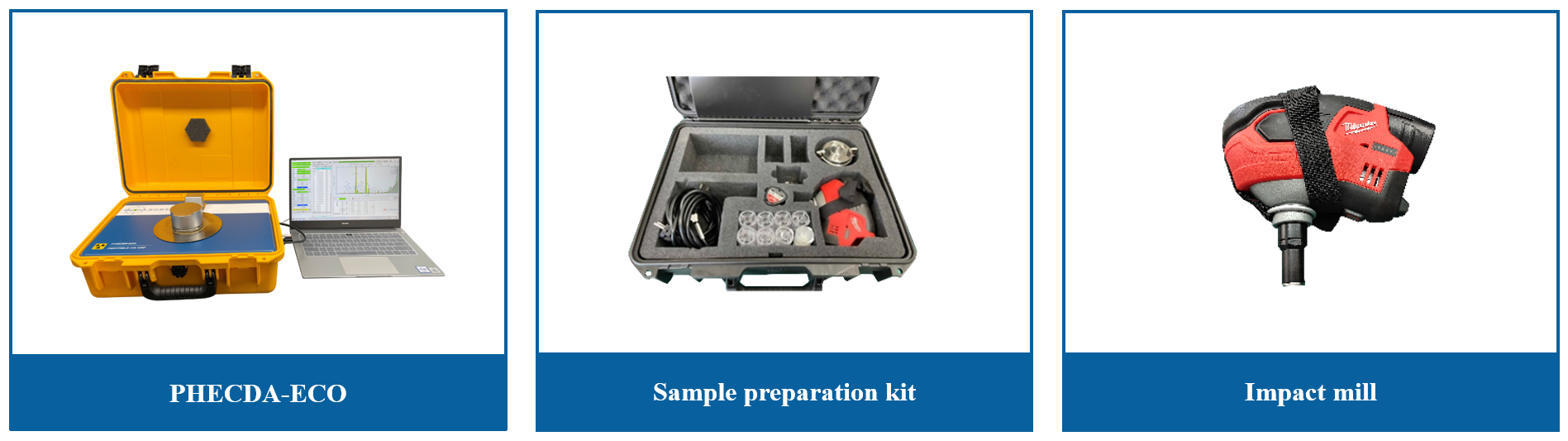

System solution

Application Features

Simple sample handling

Simple sample handling

In addition to sampling representativeness, it is only necessary to pulverize the iron ore sample on-site to particles with a fineness of millimeters;

Fast identification

Fast identification

It takes less than 10 minutes for a single sample from preparation and instrumental analysis to get the identification result;

Similarity Statistical Results

Similarity Statistical Results

90%-99.9% are iron ore, 85.0%-89.9% are suspicious samples, and <85% are non-iron ore or iron ore-doped samples;

Quantitative information of harmful elements

Quantitative information of harmful elements

Single wavelength X-ray fluorescence spectrometer with fundamental parameter method can directly obtain the quantitative results of more than 30 elements in iron ore, including the content of iron, impurity elements, harmful heavy metals and other elements.

Strong scalability

Strong scalability

OreIDs can be extended to analyze other types of ore samples and establish identification algorithms for other types of ores

Strong environmental adaptability

Strong environmental adaptability

Suitable for -10℃~40℃ environment, can complete on-site and laboratory analysis.

Note

The identification of iron ore adulterated solid waste is a very complex analysis process. This method only establishes a global iron ore database based on the element composition and content of iron ore, which cannot represent all the physical and chemical characteristics of iron ore

Original statement:

This article is the original work of ancoren company except for the quotation. If it is forwarded and quoted, the source must be indicated, otherwise it may involve infringement. For more detailed technical information, please consult the staff of Ancoren.